Benefits of Using oem ductile iron Case for casting Part

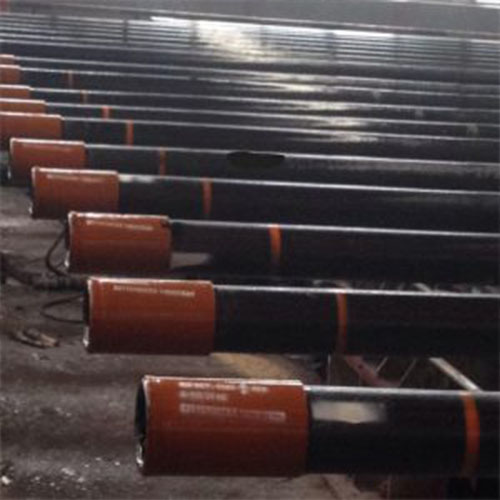

Ductile iron is a type of cast iron that has been treated with magnesium to create a more flexible and durable material. This makes it an ideal choice for a wide range of applications, including the production of OEM ductile iron cases for casting parts. There are several benefits to using OEM ductile iron cases for casting parts, which we will explore in this article.

One of the main advantages of using OEM ductile iron cases for casting parts is their strength and durability. Ductile iron is known for its high tensile strength, which makes it resistant to cracking and breaking under heavy loads. This means that OEM ductile iron cases can withstand the rigors of everyday use without compromising the integrity of the casting part.

In addition to their strength, OEM ductile iron cases are also highly resistant to wear and corrosion. This makes them an excellent choice for applications where the casting part will be exposed to harsh environments or corrosive materials. By using OEM ductile iron cases, manufacturers can ensure that their casting parts will remain in top condition for longer periods of time, reducing the need for costly repairs or replacements.

Another benefit of using OEM ductile iron cases for casting parts is their versatility. Ductile iron can be easily cast into complex shapes and designs, allowing manufacturers to create custom cases that meet their specific requirements. This flexibility makes OEM ductile iron cases an ideal choice for a wide range of industries, from automotive to aerospace.

Furthermore, OEM ductile iron cases are also cost-effective. Ductile iron is a relatively inexpensive material compared to other metals, making it an affordable option for manufacturers looking to reduce production costs. By using OEM ductile iron cases for casting parts, manufacturers can save money without sacrificing quality or performance.

In conclusion, OEM ductile iron cases offer a range of benefits for manufacturers looking to produce high-quality casting parts. From their strength and durability to their resistance to wear and corrosion, OEM ductile iron cases are a reliable and cost-effective choice for a wide range of applications. By choosing OEM ductile iron cases, manufacturers can ensure that their casting parts will perform optimally and last for years to come.

How to Choose the Right OEM Ductile Iron Case for Casting Part

When it comes to choosing the right OEM ductile iron case for a casting part, there are several factors to consider. Ductile iron is a type of cast iron that has been treated with magnesium to create a more flexible and durable material. This makes it an ideal choice for a wide range of applications, including automotive parts, machinery components, and more.

One of the first things to consider when selecting an OEM ductile iron case is the specific requirements of the casting part. different applications will have different demands in terms of strength, durability, and resistance to wear and corrosion. It is important to carefully assess these requirements in order to choose a case that will provide the necessary performance and longevity.

In addition to the specific requirements of the casting part, it is also important to consider the overall quality of the OEM ductile iron case. Look for a manufacturer that has a reputation for producing high-quality products that meet industry standards. This will help ensure that the case will perform as expected and provide reliable service over the long term.

Another important factor to consider when choosing an OEM ductile iron case is the design and construction of the case itself. Look for a case that has been carefully engineered to provide the necessary strength and durability for the application. This may include features such as reinforced corners, thick walls, and precision machining to ensure a tight fit with the casting part.

It is also important to consider the manufacturing process used to produce the OEM ductile iron case. Look for a manufacturer that uses advanced techniques and equipment to ensure consistent quality and performance. This may include processes such as precision casting, heat treatment, and quality control measures to ensure that each case meets the required specifications.

When selecting an OEM ductile iron case, it is also important to consider factors such as cost, lead time, and availability. Look for a manufacturer that can provide competitive pricing, fast turnaround times, and reliable delivery to ensure that the case will be available when needed.

cannulation procedure,

In conclusion, choosing the right OEM ductile iron case for a casting part requires careful consideration of a variety of factors. By assessing the specific requirements of the application, the quality of the case, the design and construction of the case, the manufacturing process, and other factors, it is possible to select a case that will provide the necessary performance and longevity. By working with a reputable manufacturer that offers competitive pricing, fast turnaround times, and reliable delivery, it is possible to ensure that the OEM ductile iron case will meet the needs of the application and provide reliable service over the long term.