Benefits of Using 3D printing for oem customized Auto motorcycle Spare Parts

In the world of manufacturing, the demand for customized auto and motorcycle spare parts is constantly growing. Original equipment manufacturers (OEMs) are always looking for ways to improve their products and meet the specific needs of their customers. One of the most innovative technologies that has revolutionized the production of these parts is 3D printing.

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering material on top of each other. This technology has opened up a world of possibilities for OEMs, allowing them to create complex and customized parts with ease. When it comes to auto and motorcycle spare parts, 3D printing offers a number of benefits that traditional manufacturing methods simply cannot match.

One of the key advantages of using 3D printing for OEM customized auto and motorcycle spare parts is the ability to create highly complex geometries. Traditional manufacturing methods, such as sand casting and CNC machining, are limited in the shapes and designs they can produce. With 3D printing, however, OEMs can create parts with intricate details and unique features that would be impossible to achieve using traditional methods.

Another benefit of 3D printing for OEM customized auto and motorcycle spare parts is the speed of production. Traditional manufacturing methods can be time-consuming and labor-intensive, requiring multiple steps and processes to create a single part. 3D printing, on the other hand, is a much faster and more efficient process. Parts can be designed and produced in a matter of hours, allowing OEMs to quickly respond to customer demands and market trends.

In addition to speed and complexity, 3D printing also offers cost savings for OEMs. Traditional manufacturing methods often require expensive tooling and equipment, as well as skilled labor to operate them. 3D printing, on the other hand, requires minimal setup and can be operated by a single technician. This reduces the overall cost of production and allows OEMs to create customized parts at a fraction of the cost of traditional methods.

Furthermore, 3D printing allows for greater design flexibility. OEMs can easily make changes to a part’s design and quickly produce a new prototype for testing. This iterative design process helps to reduce time-to-market and ensures that the final product meets the customer’s specifications.

Overall, the benefits of using 3D printing for OEM customized auto and motorcycle spare parts are clear. From complex geometries to cost savings and design flexibility, this technology offers a number of advantages that traditional manufacturing methods simply cannot match. As the demand for customized parts continues to grow, OEMs will increasingly turn to 3D printing as a cost-effective and efficient solution for producing high-quality spare parts.

Comparison of Sand Casting and CNC Machining for Producing engine Block Cylinder Heads

When it comes to producing engine block cylinder heads for auto and motorcycle spare parts, manufacturers have a few different options at their disposal. Two popular methods for creating these critical components are sand casting and CNC machining. Both processes have their own unique advantages and disadvantages, and understanding the differences between them can help manufacturers make informed decisions about which method is best suited for their specific needs.

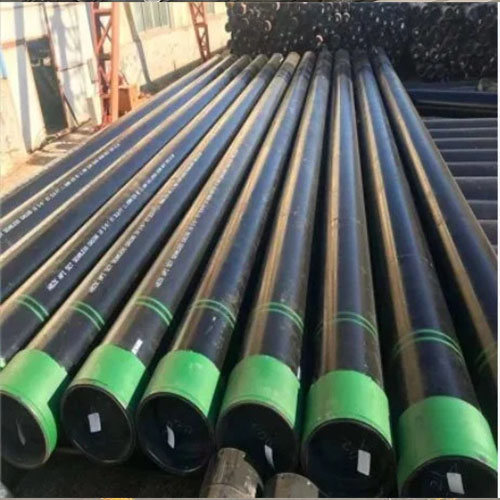

factory Selling High Quality Smooth Gmw 16171 Oil Cooler Tubing

Sand casting is a traditional method of producing metal parts that has been used for centuries. In this process, a mold is created by packing sand around a pattern of the desired part. Molten metal is then poured into the mold, where it solidifies and takes on the shape of the pattern. Once the metal has cooled, the sand mold is broken away to reveal the finished part.

One of the main advantages of sand casting is its ability to produce complex shapes with relatively low tooling costs. This makes it an attractive option for manufacturers looking to create customized or low-volume parts. Sand casting also allows for the use of a wide range of metals, including aluminum, iron, and steel, giving manufacturers flexibility in their material choices.

However, sand casting does have some limitations. The process can be time-consuming, as molds must be created and prepared before each casting. Additionally, sand casting can result in rough surfaces and dimensional inaccuracies, which may require additional finishing processes to achieve the desired final product.

On the other hand, CNC machining offers a more precise and efficient method of producing engine block cylinder heads. In this process, a computer-controlled machine removes material from a solid block of metal to create the desired shape. CNC machining is capable of producing parts with tight tolerances and smooth finishes, making it ideal for high-volume production runs.

One of the key advantages of CNC machining is its ability to produce parts with consistent quality and accuracy. This can help manufacturers reduce waste and improve overall efficiency in their production processes. CNC machining also allows for the use of a wide range of materials, including metals, plastics, and composites, giving manufacturers flexibility in their material choices.

However, CNC machining does have some drawbacks. The initial setup costs for CNC machines can be high, making it less cost-effective for small production runs. Additionally, CNC machining may not be suitable for producing extremely complex shapes or parts with intricate details, as the process relies on cutting away material rather than molding it.

In conclusion, both sand casting and CNC machining offer unique advantages and disadvantages for producing engine block cylinder heads. Sand casting is a versatile and cost-effective option for creating customized or low-volume parts, while CNC machining offers precision and efficiency for high-volume production runs. Ultimately, the choice between these two methods will depend on factors such as production volume, part complexity, and material requirements. By understanding the differences between sand casting and CNC machining, manufacturers can make informed decisions about which method is best suited for their specific needs.