Understanding the Length specifications of API 5CT casing and Tubing

The length specifications of API 5CT casing and tubing play a critical role in the Oil and gas industry, ensuring seamless operations and optimal performance in drilling and extraction processes. Understanding these specifications is essential for professionals in the field to effectively manage resources and maintain safety standards.

API 5CT, developed by the american petroleum Institute (API), sets standards for the manufacturing and usage of casing and tubing in the oil and gas sector. These standards encompass various aspects, including material composition, dimensions, and testing procedures. Length specifications are among the key parameters outlined in the API 5CT standards, governing the size and range of casing and tubing used in drilling operations.

10mm oil Pipe 25m

Casing and tubing lengths are typically measured in feet or meters, with standard lengths defined by API 5CT to ensure compatibility and consistency across different applications. The standard lengths are designed to accommodate the requirements of drilling rigs and well designs, allowing for efficient installation and operation in diverse geological conditions.

oil pipe on carAPI 5CT casing lengths commonly range from 20 to 48 feet, with each length serving specific purposes based on well depth, casing design, and operational requirements. Longer casing lengths are often preferred for deeper wells to minimize the number of connections and reduce the risk of leakage or structural issues. Conversely, shorter lengths may be used in shallow wells or when space constraints dictate a more compact design.

Tubing lengths adhere to similar standards, typically ranging from 28 to 32 feet, although customized lengths can be manufactured to meet specific project needs. The choice of tubing length depends on factors such as well depth, production methods, and surface equipment configurations, with longer lengths offering advantages in terms of efficiency and cost-effectiveness.

Oil Field couplings

Transitional phrases such as “conversely,” “similarly,” and “although” help guide the reader through the discussion, highlighting the interconnectedness of different concepts. These phrases facilitate a smooth flow of ideas, enhancing the clarity and coherence of the article.

In addition to standard lengths, API 5CT also specifies tolerance limits for casing and tubing dimensions to ensure uniformity and quality control in manufacturing processes. These tolerance limits help mitigate the risk of deviations that could compromise the integrity or performance of casing and tubing components, ensuring reliability and safety in oil and gas operations.

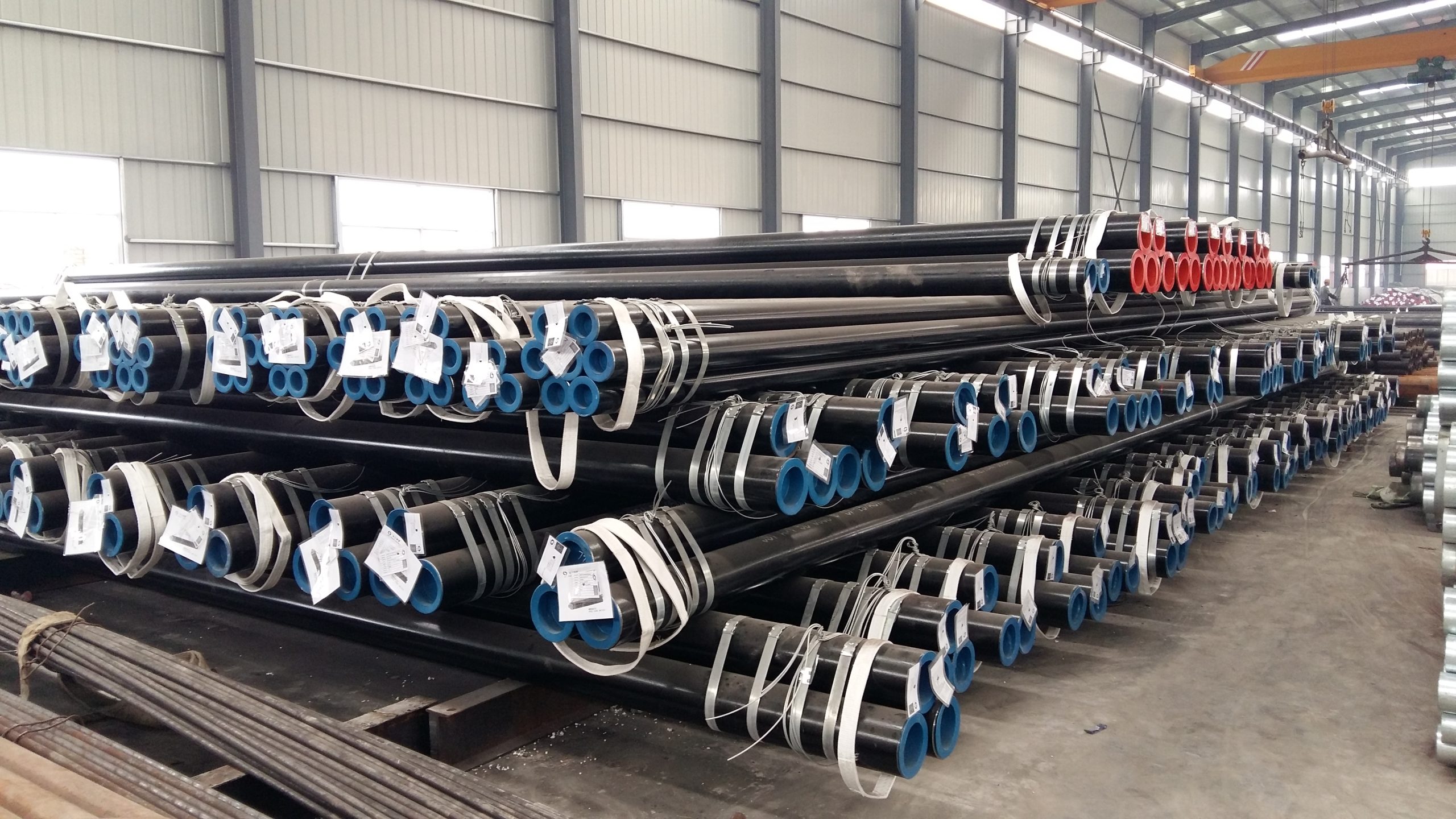

Furthermore, API 5CT provides guidelines for handling, storage, and transportation of casing and tubing to prevent damage or contamination during transit and storage. Proper handling procedures are essential to preserving the structural integrity and performance characteristics of casing and tubing, safeguarding against potential hazards and operational disruptions.

In conclusion, the length specifications of API 5CT casing and tubing are integral to the efficiency, safety, and reliability of oil and gas drilling operations. By adhering to standardized lengths and tolerance limits, industry professionals can optimize resource utilization, mitigate risks, and ensure consistent performance in diverse geological environments. Understanding these specifications is paramount for effective project planning, execution, and regulatory compliance in the dynamic and challenging landscape of the oil and gas industry.