Exploring the Importance of API standards in manufacturing Processes

API Standards for Manufacturing and API casing Chart

Exploring the Importance of API Standards in Manufacturing Processes

In the realm of manufacturing, adherence to standards is paramount. It ensures consistency, quality, and safety across various industries. One such set of standards that holds significant importance, particularly in the Oil and gas sector, is the american petroleum Institute (API) standards. these standards provide guidelines and specifications for various aspects of manufacturing, including equipment, materials, and processes.

API standards serve as a benchmark for manufacturers, helping them produce products that meet industry requirements and regulatory compliance. they cover a wide range of areas, from drilling equipment to production Tubing, and are continuously updated to reflect technological advancements and evolving industry needs.

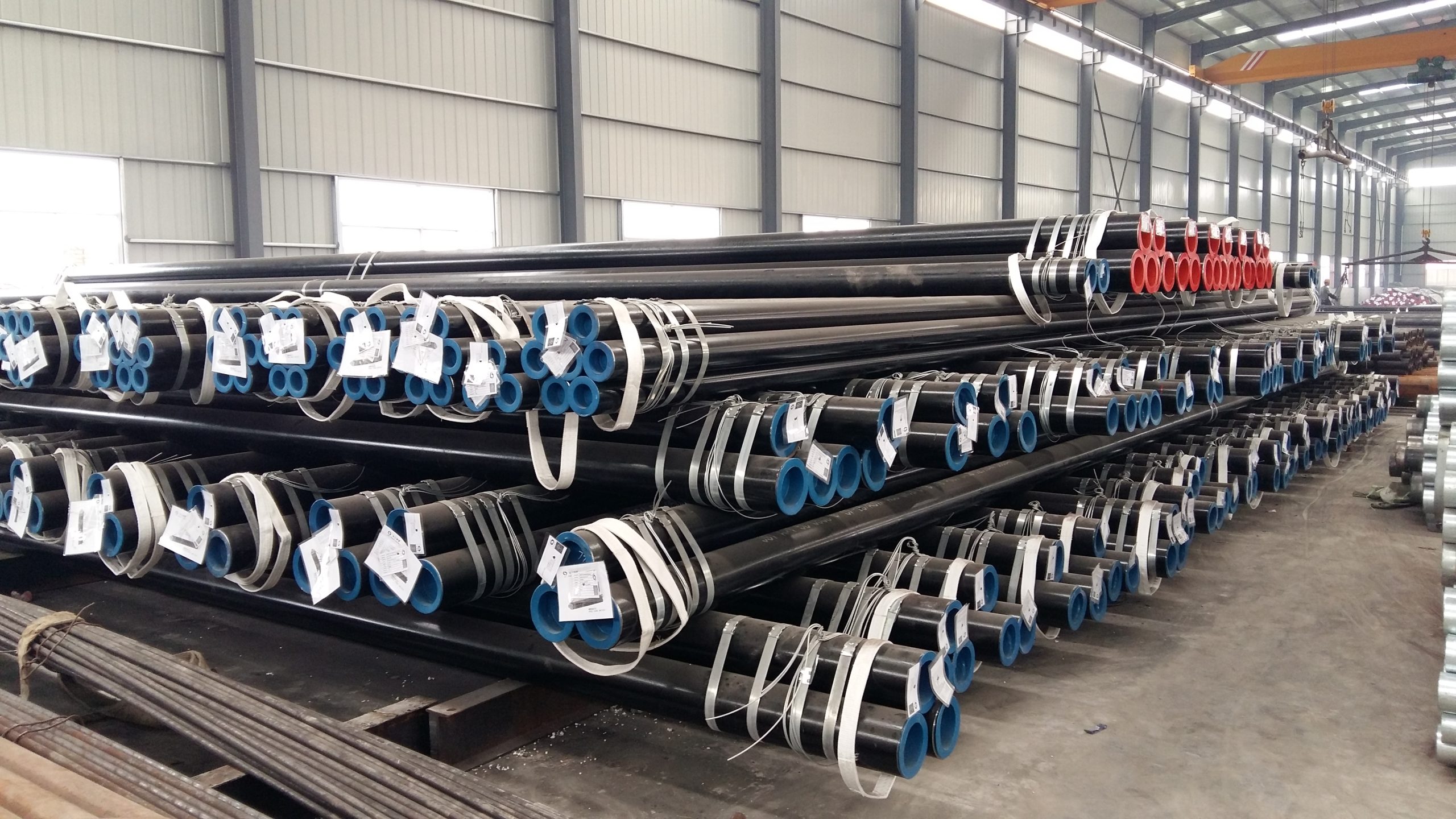

wholesale casing Pipe exporters

When it comes to oil and gas exploration and production, API standards play a crucial role in ensuring the integrity and reliability of equipment used in these operations. One area where API standards are particularly vital is in the manufacturing of casing and tubing – essential components of oil and gas wells.

API casing and tubing specifications define the requirements for the design, material, dimensions, and testing of these components. They provide detailed guidelines for manufacturers to follow, ensuring that casing and tubing meet the performance and safety standards necessary for downhole applications.

Manufacturers rely on API standards to produce casing and tubing that can withstand the harsh conditions encountered in oil and gas wells, including high pressure, high temperature, and corrosive environments. By adhering to these standards, manufacturers can ensure the durability and reliability of their products, minimizing the risk of failure during drilling and production operations.

One of the key aspects of API standards for casing and tubing is the API casing chart. This chart provides detailed information on the dimensions, weights, and mechanical properties of various casing and tubing sizes. It serves as a valuable reference tool for engineers, designers, and manufacturers involved in well construction and completion.

The API casing chart includes data such as outside diameter, wall thickness, weight per unit length, and collapse and burst pressures for different casing and tubing sizes and grades. This information helps stakeholders select the appropriate casing and tubing specifications for specific well conditions and operating parameters.

By using the API casing chart, engineers can ensure that the casing and tubing selected for a particular well design meet the necessary performance criteria and regulatory requirements. It allows for informed decision-making regarding the selection of materials and specifications, optimizing well construction and production processes.

casing head oil definitionFurthermore, the API casing chart facilitates communication and collaboration among stakeholders involved in well construction and completion. Engineers, drilling contractors, and equipment suppliers can easily reference the same set of data, ensuring consistency and alignment throughout the project lifecycle.

In conclusion, API standards play a critical role in the manufacturing processes of oil and gas equipment, including casing and tubing. These standards provide guidelines and specifications that help ensure the integrity, reliability, and safety of equipment used in drilling and production operations. The API casing chart, in particular, serves as a valuable tool for engineers and manufacturers, providing essential data for the selection and design of casing and tubing for oil and gas wells. By adhering to API standards and utilizing resources such as the API casing chart, manufacturers can contribute to the overall efficiency and success of oil and gas projects while maintaining the highest standards of quality and safety.

Understanding the Significance of API Casing Charts in Oil and Gas Industry

API Standards for Manufacturing and API Casing Chart

In the intricate world of oil and gas extraction, precision and consistency are paramount. Every component involved must meet rigorous standards to ensure safety, efficiency, and effectiveness. Among these crucial components is the API casing, a fundamental element in drilling operations. Understanding the significance of API casing charts is essential for professionals in the oil and gas industry.

API, or the American Petroleum Institute, sets forth standards that govern the manufacturing and use of various equipment and materials in the oil and gas sector. These standards are meticulously developed through collaboration among industry experts, regulators, and stakeholders to establish best practices and ensure operational integrity. For casing, API specifications delineate requirements for materials, dimensions, mechanical properties, and testing procedures.

API casing charts serve as comprehensive references that outline the specifications for different types and grades of casing. They provide detailed information on dimensions, weights, and performance characteristics, enabling engineers and operators to select the most suitable casing for specific well conditions and drilling environments. By adhering to these standards, companies can maintain consistency in their operations and mitigate risks associated with equipment failure or non-compliance.

CT80 Coiled Tubing

The API casing chart typically includes data on casing size, weight per unit length, internal and external diameters, wall thickness, and connection type. Additionally, it may specify material composition, yield strength, and tensile strength, crucial factors in determining casing suitability for different wellbore conditions and depths. This wealth of information empowers engineers to make informed decisions during the design and planning phases of drilling projects.

Transitional Phrases:

“Moving forward,” “Moreover,” “Furthermore,” “In addition to that,” “Consequently,” “As a result,” “Therefore,” “Subsequently.”

Moving forward, API casing charts play a pivotal role in ensuring operational efficiency and integrity throughout the lifecycle of a well. During drilling operations, accurate selection and deployment of casing are essential for wellbore stability, fluid containment, and zonal isolation. Engineers rely on API standards and casing charts to identify the appropriate casing grade and size that can withstand anticipated downhole pressures, temperatures, and mechanical stresses.

Moreover, API casing charts facilitate effective communication and collaboration among stakeholders involved in drilling projects. Contractors, suppliers, and regulatory agencies can refer to these standardized documents to verify compliance and resolve discrepancies. By adhering to a common set of specifications, the industry fosters transparency, consistency, and accountability in equipment procurement and installation processes.

Furthermore, API casing charts serve as valuable educational resources for professionals entering the oil and gas industry. New engineers and technicians can familiarize themselves with industry terminology, equipment specifications, and performance requirements by studying these comprehensive guides. As they gain experience, they can leverage API standards to optimize well designs, troubleshoot operational challenges, and implement best practices in their respective fields.

In addition to that, API casing charts evolve in response to technological advancements, industry trends, and lessons learned from past experiences. Revisions and updates to API specifications reflect ongoing efforts to enhance safety, efficiency, and environmental stewardship in oil and gas operations. Engineers and operators must stay abreast of these changes to ensure compliance and adaptability in their practices.

Consequently, API casing charts serve as living documents that reflect the collective wisdom and innovation of the oil and gas industry. They embody years of research, testing, and collaboration aimed at continuously improving drilling practices and minimizing risks. By embracing API standards and leveraging the insights provided by casing charts, companies can enhance their competitiveness, sustainability, and resilience in a dynamic global market.

As a result, understanding the significance of API casing charts is essential for professionals engaged in oil and gas exploration and production. These documents encapsulate the principles of quality assurance, risk management, and performance optimization that underpin the industry’s success. By adhering to API standards and embracing the guidance provided by casing charts, stakeholders can navigate the complexities of drilling operations with confidence and competence.

Therefore, API casing charts represent more than just technical specifications; they symbolize a commitment to excellence, integrity, and collaboration in the pursuit of energy resources. As the oil and gas industry continues to evolve, API standards and casing charts will remain indispensable tools for achieving operational excellence and sustainable development.