Benefits of Using Welded steel Pipes in industrial Applications

Welded steel pipes are a crucial component in various industrial applications due to their practicality and performance. these pipes are made by welding steel plates together to form a cylindrical shape, providing a durable and reliable solution for transporting fluids, gases, and other materials in industrial settings. In this article, we will explore the benefits of using welded steel pipes in industrial applications.

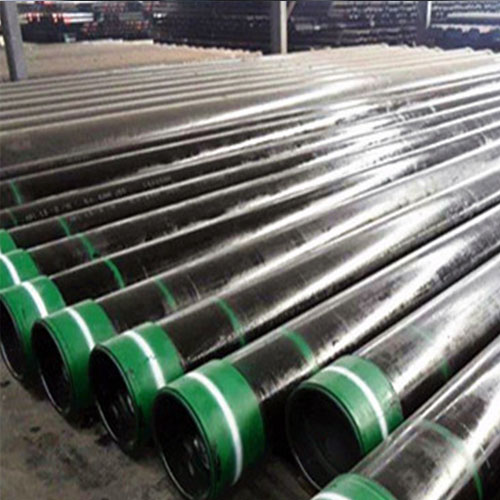

One of the key advantages of welded steel pipes is their strength and durability. These pipes are able to withstand high pressure and temperature conditions, making them ideal for use in industries such as Oil and gas, construction, and manufacturing. The welded seams of these pipes are able to hold up against the stresses of transportation and handling, ensuring that they remain intact and leak-free throughout their lifespan.

Additionally, welded steel pipes are highly resistant to corrosion, making them a cost-effective and long-lasting solution for industrial applications. The protective coating on these pipes helps to prevent rust and deterioration, ensuring that they maintain their structural integrity over time. This resistance to corrosion also makes welded steel pipes suitable for use in harsh environments, such as chemical plants and offshore drilling platforms.

Another benefit of using welded steel pipes in industrial applications is their versatility. These pipes can be manufactured in a wide range of sizes and thicknesses, making them suitable for a variety of applications. Whether you need a small diameter pipe for a residential plumbing project or a large diameter pipe for a major construction project, welded steel pipes can be customized to meet your specific requirements.

Gift BoxFurthermore, welded steel pipes are easy to install and maintain, reducing downtime and increasing efficiency in industrial operations. The welded joints of these pipes provide a secure connection that is less prone to leaks and failures, ensuring that your system operates smoothly and reliably. Additionally, the smooth interior surface of welded steel pipes allows for efficient flow of materials, reducing friction and energy loss in the system.

men stuck in oil pipeIn conclusion, welded steel pipes offer a range of benefits for industrial applications, including strength, durability, corrosion resistance, versatility, and ease of installation. These pipes are a practical and reliable solution for transporting fluids, gases, and other materials in a variety of industries. Whether you are working in oil and gas, construction, manufacturing, or any other industrial sector, welded steel pipes can provide the performance and reliability you need to keep your operations running smoothly. Consider using welded steel pipes for your next industrial project and experience the benefits firsthand.

How to Ensure Optimal Performance of Welded Steel Pipes in industry

Welded steel pipes are a crucial component in various industries, including construction, oil and gas, and manufacturing. These pipes are known for their durability, strength, and versatility, making them a popular choice for transporting liquids, gases, and solids. However, to ensure optimal performance and longevity of welded steel pipes in industrial applications, proper maintenance and care are essential.

One of the key factors in ensuring the optimal performance of welded steel pipes is proper installation. It is crucial to follow the manufacturer‘s guidelines and recommendations when installing welded steel pipes to prevent any potential issues such as leaks, cracks, or corrosion. Additionally, ensuring that the pipes are properly aligned and supported during installation can help prevent stress and strain on the pipes, which can lead to premature failure.

tianchang kanghong oil pipe companyRegular inspection and maintenance are also essential for ensuring the optimal performance of welded steel pipes in industry. Inspecting the pipes for any signs of damage, corrosion, or wear and tear can help identify potential issues before they escalate into more significant problems. Regular maintenance, such as cleaning, painting, and coating the pipes, can help prevent corrosion and extend the lifespan of the pipes.

Another crucial aspect of ensuring the optimal performance of welded steel pipes is monitoring the operating conditions. Factors such as temperature, pressure, and flow rate can impact the performance and integrity of welded steel pipes. Monitoring these operating conditions regularly can help identify any potential issues and allow for timely intervention to prevent any damage or failure.

In addition to proper installation, inspection, and maintenance, choosing the right type of welded steel pipes for the specific application is essential for ensuring optimal performance. Factors such as the material grade, wall thickness, and diameter of the pipes should be carefully considered to ensure that they can withstand the operating conditions and requirements of the industry. Consulting with a professional engineer or manufacturer can help determine the most suitable type of welded steel pipes for the application.

Furthermore, proper handling and storage of welded steel pipes are crucial for maintaining their performance and integrity. Storing the pipes in a dry, well-ventilated area away from moisture, chemicals, and other contaminants can help prevent corrosion and damage. Additionally, handling the pipes with care and using proper lifting and transportation equipment can prevent any physical damage that can compromise the integrity of the pipes.

In conclusion, welded steel pipes are a practical and reliable choice for various industrial applications due to their durability, strength, and versatility. To ensure optimal performance and longevity of welded steel pipes in industry, proper installation, inspection, maintenance, monitoring of operating conditions, and choosing the right type of pipes are essential. By following these guidelines and best practices, industries can maximize the performance and efficiency of welded steel pipes, ultimately leading to safer and more reliable operations.