Environmental Impact of Welded steel Pipes

Welded steel pipes are a common choice for various applications due to their affordability and durability. However, the long-term environmental impact of using welded steel pipes is a topic that deserves attention. While these pipes offer many benefits, such as strength and resistance to corrosion, they also have a significant impact on the environment throughout their lifecycle.

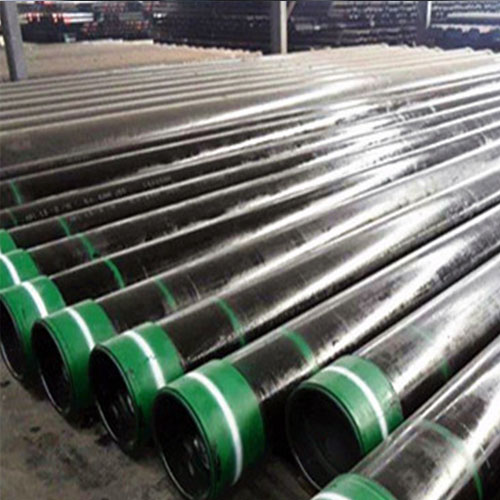

casing for Oil wellsOne of the primary environmental concerns associated with welded steel pipes is the energy consumption and greenhouse gas emissions involved in their production. The manufacturing process of welded steel pipes requires a substantial amount of energy, primarily from burning fossil fuels. This energy consumption contributes to the release of greenhouse gases, such as carbon dioxide, into the atmosphere, which is a major driver of climate change.

Titanium PipesFurthermore, the extraction of raw materials for steel production, such as iron ore and coal, can have detrimental effects on the environment. mining activities can lead to deforestation, habitat destruction, and water pollution, impacting local ecosystems and wildlife. Additionally, the transportation of these raw materials to steel mills and the distribution of finished welded steel pipes also contribute to carbon emissions and air pollution.

Once welded steel pipes are in use, they can have a lasting impact on the environment if not properly maintained. Corrosion and leaks in pipes can lead to the release of harmful substances into the soil and water, posing a threat to human health and the environment. Inadequate maintenance of welded steel pipes can also result in costly repairs and replacements, further increasing the environmental footprint of these products.

Despite these environmental concerns, there are ways to mitigate the impact of welded steel pipes on the environment. One approach is to improve the efficiency of steel production processes by using renewable energy sources and implementing recycling programs. Recycling steel reduces the need for new raw materials, conserves energy, and minimizes waste, ultimately lowering the environmental impact of welded steel pipes.

Another strategy is to invest in alternative materials that have a lower environmental footprint, such as plastic or composite pipes. These materials are lighter, easier to install, and have a longer lifespan than welded steel pipes, reducing the need for frequent replacements and repairs. Additionally, advancements in technology have led to the development of eco-friendly coatings and linings for steel pipes, which can help prevent corrosion and extend their service life.

In conclusion, while welded steel pipes offer affordability and durability, their long-term environmental impact should not be overlooked. The production, use, and disposal of these pipes have significant implications for the environment, including energy consumption, greenhouse gas emissions, and habitat destruction. By implementing sustainable practices and exploring alternative materials, we can reduce the environmental footprint of welded steel pipes and move towards a more sustainable future.

Maintenance and Durability of Welded Steel Pipes

Welded steel pipes are a popular choice for various applications due to their affordability and durability. However, while these pipes may seem like a cost-effective option in the short term, it is essential to consider their long-term maintenance and durability to determine if they are truly a cost-effective solution.

One of the key factors to consider when evaluating the long-term cost of welded steel pipes is their maintenance requirements. While welded steel pipes are known for their strength and durability, they are not immune to wear and tear over time. Regular maintenance is essential to ensure that these pipes remain in optimal condition and continue to perform effectively.

Routine inspections are crucial to identify any signs of corrosion, leaks, or other issues that could compromise the integrity of the pipes. By catching these issues early on, maintenance can be performed promptly to prevent further damage and extend the lifespan of the pipes. Neglecting maintenance can lead to costly repairs or even the need for replacement, significantly increasing the long-term cost of using welded steel pipes.

oil valve cover sludge

In addition to regular inspections, proper cleaning and coating of welded steel pipes are essential for maintaining their durability. Corrosion is a common issue that can affect the longevity of steel pipes, especially in environments with high humidity or exposure to corrosive substances. Applying protective coatings can help prevent corrosion and extend the lifespan of the pipes, reducing the need for frequent repairs or replacements.

Another factor to consider when evaluating the long-term cost of welded steel pipes is their resistance to external factors such as temperature fluctuations and pressure changes. Welded steel pipes are known for their strength and ability to withstand high pressure, making them suitable for a wide range of applications. However, exposure to extreme temperatures or pressure fluctuations can affect the performance of these pipes over time.

Proper insulation and support are essential to protect welded steel pipes from temperature fluctuations and pressure changes. Insulation helps maintain the temperature of the pipes, preventing them from expanding or contracting excessively in response to changes in temperature. Adequate support also helps distribute the weight of the pipes evenly, reducing the risk of structural damage due to pressure changes.

Overall, while welded steel pipes are an affordable option for various applications, it is essential to consider their long-term maintenance and durability to determine their true cost-effectiveness. Regular inspections, proper cleaning and coating, and protection from external factors are crucial for ensuring that these pipes remain in optimal condition and continue to perform effectively over time. By investing in proper maintenance and care, welded steel pipes can provide a cost-effective solution for various applications while minimizing the risk of costly repairs or replacements in the long run.