The Environmental Impact of Welded steel Pipes

Welded steel pipes are a popular choice in various industries due to their durability, strength, and cost-effectiveness. However, the production and use of welded steel pipes come with environmental costs that are often overlooked. In this article, we will explore the environmental impact of welded steel pipes and the implications for our planet.

The production of welded steel pipes involves the extraction of raw materials such as iron ore, coal, and limestone. these materials are then processed in blast furnaces to produce steel, which is subsequently formed into pipes through welding processes. The extraction and processing of raw materials require significant energy inputs, leading to greenhouse gas emissions and air pollution. Additionally, the transportation of raw materials and finished products further contributes to carbon emissions and environmental degradation.

case 930 transmission Oil

The welding process itself also has environmental implications. Welding operations typically use high temperatures and produce fumes and gases that can be harmful to human health and the environment. These emissions can contain pollutants such as particulate matter, volatile organic compounds, and heavy metals, which can have long-term effects on air quality and ecosystem health. Furthermore, the use of welding consumables such as electrodes and shielding gases can result in additional environmental impacts through resource extraction and waste generation.

factorio oil pipe or trainOnce welded steel pipes are manufactured, they are used in various applications such as water and gas distribution, oil and gas pipelines, and structural support in buildings and infrastructure. While steel pipes are known for their longevity and recyclability, their use can still have environmental consequences. For example, the transportation and installation of steel pipes can result in habitat destruction, soil erosion, and water pollution. Additionally, the maintenance and repair of steel pipelines can lead to leaks and spills that can contaminate soil and water sources.

Despite these environmental costs, welded steel pipes remain a cost-effective and versatile option for many industries. However, it is essential for manufacturers, suppliers, and end-users to consider the environmental impact of welded steel pipes and take steps to mitigate their effects. This can be achieved through the adoption of sustainable practices such as using recycled steel, optimizing production processes to reduce energy consumption, and implementing proper waste management strategies.

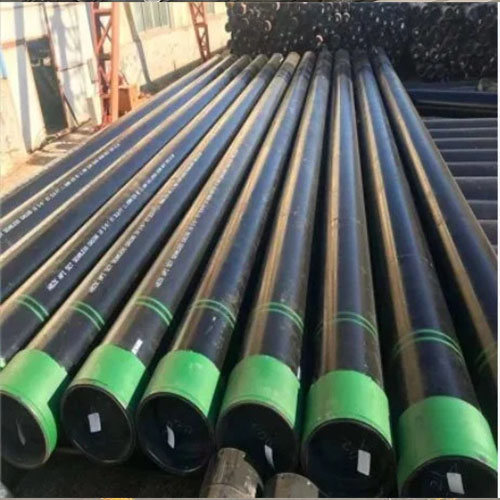

Oil casing TubeIn conclusion, welded steel pipes offer numerous benefits in terms of strength, durability, and affordability. However, the environmental impact of their production and use cannot be ignored. It is crucial for stakeholders in the steel industry to prioritize sustainability and environmental stewardship in order to minimize the negative effects of welded steel pipes on our planet. By taking proactive measures to reduce emissions, conserve resources, and protect ecosystems, we can ensure that welded steel pipes continue to be a viable and responsible choice for the future.