Benefits of Using Slip Type casing Hanger with Integral high pressure Isolation Plate

Slip type casing hangers with integral high pressure isolation plates are essential components in Oil and gas well completions. these innovative tools provide a secure and reliable means of suspending casing strings in the wellbore while also offering a high-pressure isolation barrier to protect against wellbore fluids. The benefits of using slip type casing hangers with integral high pressure isolation plates are numerous and can greatly enhance the efficiency and safety of well operations.

One of the key advantages of slip type casing hangers with integral high pressure isolation plates is their ability to provide a secure and reliable means of suspending casing strings in the wellbore. The slip type design allows for easy installation and removal of the casing string, while also providing a strong grip on the casing to prevent any movement or slippage during well operations. This ensures that the casing string remains securely in place, even under high pressure and temperature conditions.

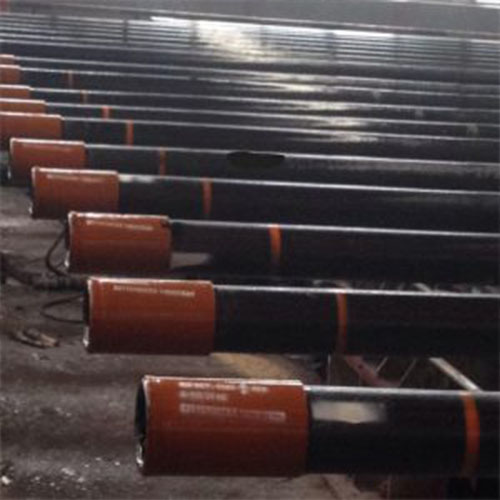

casing oilfield servicesIn addition to providing a secure means of suspending casing strings, slip type casing hangers with integral high pressure isolation plates also offer a high-pressure isolation barrier to protect against wellbore fluids. The integral isolation plate is designed to withstand high pressure and temperature conditions, providing a reliable barrier to prevent the migration of fluids between the casing and the wellbore. This helps to maintain well integrity and prevent any potential leaks or blowouts that could pose a risk to personnel and the environment.

cannula needle,

Another benefit of using slip type casing hangers with integral high pressure isolation plates is their versatility and compatibility with a wide range of well completion systems. These hangers can be easily integrated into various well designs and configurations, making them suitable for both onshore and offshore applications. Whether used in vertical, deviated, or horizontal wells, slip type casing hangers with integral high pressure isolation plates can provide a reliable solution for suspending casing strings and protecting against wellbore fluids.

Furthermore, slip type casing hangers with integral high pressure isolation plates are designed to withstand the harsh conditions encountered in oil and gas well completions. The materials used in their construction are highly durable and resistant to corrosion, erosion, and other forms of degradation that can occur in downhole environments. This ensures that the hangers will maintain their integrity and performance over an extended period, reducing the need for frequent maintenance or replacement.

Overall, slip type casing hangers with integral high pressure isolation plates offer a range of benefits that can greatly enhance the efficiency and safety of well completions. From providing a secure means of suspending casing strings to offering a high-pressure isolation barrier, these hangers are essential components in ensuring the integrity and reliability of oil and gas well operations. Their versatility, durability, and compatibility with various well designs make them a valuable asset for any well completion system. By incorporating slip type casing hangers with integral high pressure isolation plates into well designs, operators can improve operational efficiency, reduce risks, and ensure the success of their well completions.

Installation and Maintenance Tips for Slip Type Casing Hanger with Integral High Pressure Isolation Plate

Slip type casing hangers with integral high pressure isolation plates are essential components in oil and gas well completions. These hangers provide a reliable means of suspending and sealing the casing string in the wellbore, ensuring the integrity of the well and preventing any leaks or blowouts. Proper installation and maintenance of these hangers are crucial to ensure their effectiveness and longevity.

yellow oil burner PipeDuring the installation of slip type casing hangers with integral high pressure isolation plates, it is important to follow the manufacturer‘s guidelines and recommendations. This includes ensuring that the hanger is properly sized and rated for the specific well conditions, including pressure and temperature. The hanger should be installed using the correct tools and equipment, and care should be taken to ensure that it is properly aligned and seated in the wellhead.

Once the hanger is installed, it is important to conduct regular inspections and maintenance to ensure its continued performance. This includes checking for any signs of wear or damage, such as corrosion or erosion, and replacing any worn or damaged components as needed. It is also important to check the integrity of the isolation plate to ensure that it is providing the necessary pressure containment.

In addition to regular inspections, it is also important to conduct pressure testing of the slip type casing hanger with integral high pressure isolation plate. This involves pressurizing the wellbore to the maximum expected pressure and monitoring for any leaks or failures in the hanger or isolation plate. Any issues that are identified during the pressure test should be addressed immediately to prevent any potential safety hazards.

Proper maintenance of slip type casing hangers with integral high pressure isolation plates is essential to ensure the safety and integrity of the well. This includes keeping the hanger clean and free of debris, as well as ensuring that all seals and gaskets are in good condition. It is also important to follow the manufacturer’s recommended maintenance schedule and procedures to ensure that the hanger continues to perform effectively.

In conclusion, slip type casing hangers with integral high pressure isolation plates are critical components in oil and gas well completions. Proper installation and maintenance of these hangers are essential to ensure their effectiveness and longevity. By following the manufacturer’s guidelines and recommendations, conducting regular inspections and maintenance, and performing pressure testing as needed, operators can ensure the safety and integrity of their wells. Proper maintenance of slip type casing hangers with integral high pressure isolation plates is essential to ensure the safety and integrity of the well.