Advantages of Using C Oiled Tubing in Oil Well tools

Coiled tubing is a vital tool in the oil and gas industry, providing a cost-effective and efficient solution for various well intervention and completion operations. One of the key advantages of using coiled tubing in oil well tools is its flexibility and ability to reach deep into wellbores without the need for multiple joints and connections. This seamless stainless steel tubing is designed to withstand high pressure and temperature conditions, making it ideal for a wide range of applications in the oil and gas sector.

The seamless construction of coiled tubing eliminates the risk of leaks and failures that can occur with traditional jointed tubing systems. This not only improves safety on the job site but also reduces downtime and maintenance costs associated with repairing or replacing damaged tubing. In addition, the smooth surface of seamless stainless steel tubing minimizes friction and drag, allowing for faster and more efficient operations in the wellbore.

Another advantage of using coiled tubing in oil well tools is its ability to perform a variety of tasks in a single run. Coiled tubing can be used for well cleaning, acidizing, cementing, and other well intervention operations without the need to remove and replace the tubing between tasks. This saves time and money by reducing the number of trips in and out of the wellbore, as well as minimizing the risk of damaging the wellbore or downhole equipment.

Coiled tubing is also highly versatile and can be customized to meet the specific requirements of each well. different sizes and grades of seamless stainless steel tubing are available to accommodate various well depths, pressures, and temperatures. This flexibility allows operators to optimize their operations and achieve better results in a cost-effective manner.

Furthermore, coiled tubing is a more environmentally friendly option compared to traditional methods of well intervention. The seamless construction of coiled tubing reduces the risk of spills and leaks, minimizing the impact on the surrounding environment. In addition, the ability to perform multiple tasks in a single run reduces the need for additional equipment and resources, further reducing the carbon footprint of oil and gas operations.

Overall, the advantages of using coiled tubing in oil well tools are clear. Its flexibility, durability, efficiency, and environmental benefits make it a valuable tool for operators looking to optimize their well intervention and completion operations. With seamless stainless steel tubing, operators can trust that their operations will be safe, reliable, and cost-effective, helping them achieve their production goals while minimizing risks and environmental impact.

In conclusion, coiled tubing is a game-changer in the oil and gas industry, offering a wide range of advantages for operators looking to improve their well intervention and completion operations. Its seamless construction, flexibility, efficiency, and environmental benefits make it a valuable tool for any well site. By investing in coiled tubing technology, operators can enhance their operations, reduce costs, and minimize risks, ultimately leading to greater success in the oil and gas sector.

How Seamless Stainless Steel Coiled Tubing Improves Performance in Oil Well Operations

Oil well operations require precision and efficiency to ensure the successful extraction of oil and gas from deep within the earth. One crucial component of these operations is the use of coiled tubing, a continuous length of steel or stainless steel tubing wound on a spool. Coiled tubing is used in a variety of applications in the oil and gas industry, including well intervention, well cleaning, and hydraulic fracturing. In recent years, seamless stainless steel coiled tubing has become increasingly popular due to its superior performance and durability compared to traditional steel tubing.

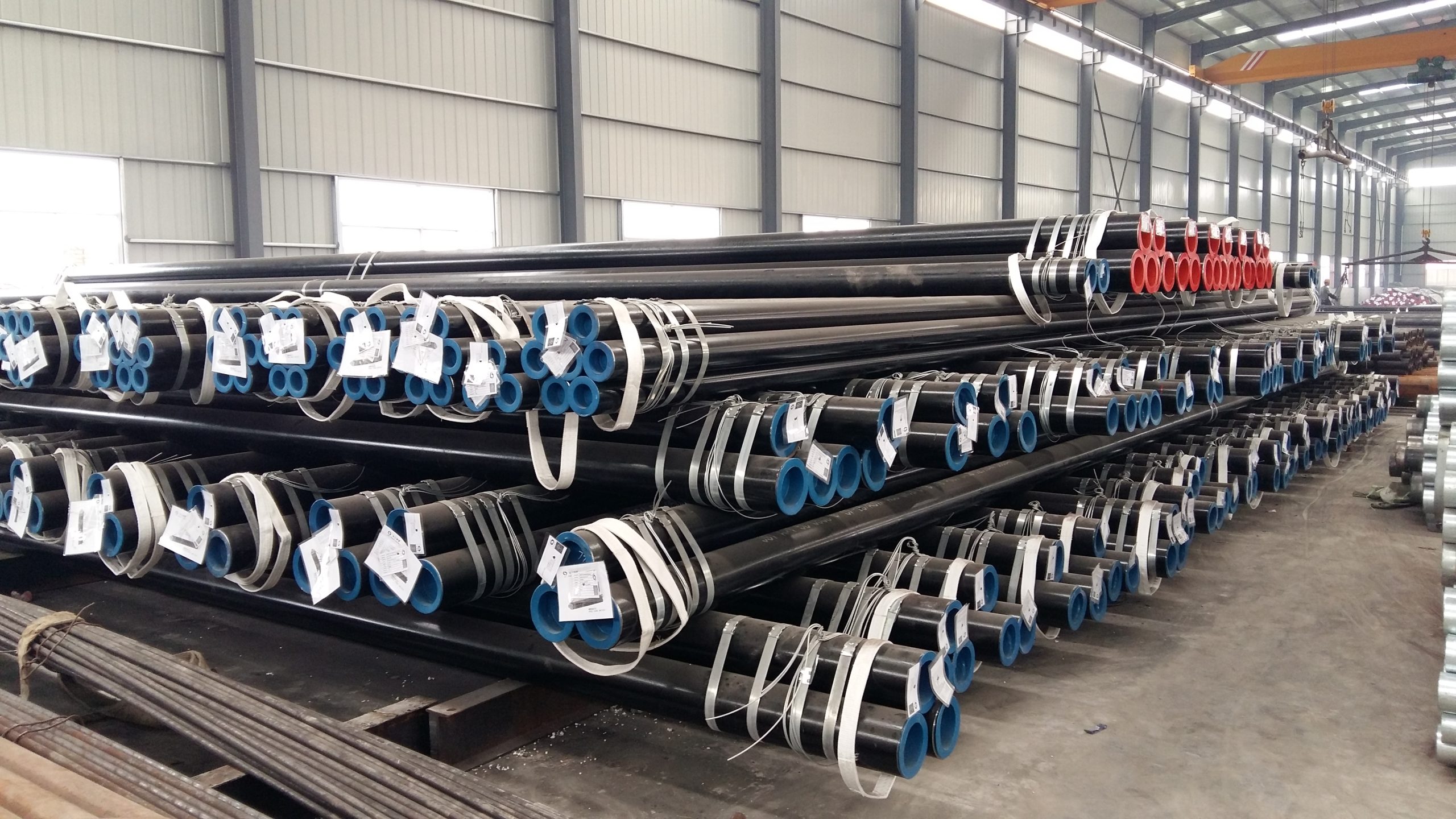

casing Pipe China best wholesaler

Seamless stainless steel coiled tubing is manufactured using a seamless process, which eliminates the need for welding seams that can weaken the tubing and make it more susceptible to corrosion. This seamless construction provides a smooth, uniform surface that reduces friction and allows for easier insertion and retrieval of the tubing in the wellbore. Additionally, stainless steel is highly resistant to corrosion, making it ideal for use in harsh environments such as oil wells where exposure to corrosive fluids and high temperatures is common.

The use of seamless stainless steel coiled tubing in oil well operations offers several key advantages over traditional steel tubing. One of the main benefits is its superior strength and durability. Stainless steel is known for its high tensile strength and resistance to deformation, making it less likely to fail under the high pressures and stresses encountered in oil well operations. This increased strength and durability translate to longer service life and reduced downtime, ultimately leading to cost savings for oil companies.

Another advantage of seamless stainless steel coiled tubing is its enhanced performance in high-temperature environments. Stainless steel can withstand extreme temperatures without losing its structural integrity, making it well-suited for use in oil wells where temperatures can reach hundreds of degrees Fahrenheit. This thermal stability ensures that the tubing maintains its shape and performance even under the most challenging conditions, allowing for more efficient and reliable operation of oil well equipment.

In addition to its strength and thermal stability, seamless stainless steel coiled tubing offers improved corrosion resistance compared to traditional steel tubing. Corrosion is a major concern in oil well operations, as exposure to corrosive fluids can cause steel tubing to degrade and fail prematurely. Stainless steel, on the other hand, is highly resistant to corrosion, making it a more reliable and long-lasting option for use in oil wells. This corrosion resistance not only extends the service life of the tubing but also reduces the risk of costly repairs and replacements.

Overall, seamless stainless steel coiled tubing is a superior choice for oil well operations due to its strength, durability, thermal stability, and corrosion resistance. By investing in high-quality stainless steel tubing, oil companies can improve the performance and reliability of their operations, leading to increased productivity and cost savings in the long run. As the demand for oil and gas continues to grow, the use of seamless stainless steel coiled tubing will play an increasingly important role in ensuring the efficiency and success of oil well operations.