Importance of material composition in Oil casing

Oil casing is a critical component in the oil drilling process, providing structural support and protection for the wellbore. The material composition of oil casing plays a crucial role in determining its performance and longevity in harsh drilling environments. In this article, we will discuss the importance of comparative indicators of oil casing materials and why they are essential for ensuring the success of oil drilling operations.

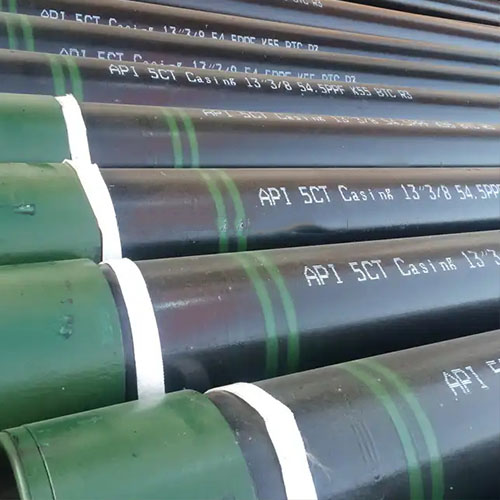

China factory 20# seamless Thick wall Oil Pipe Fluid pipeline high quality 10# gas carbon steel Tube Higher Quality and Lower price

One of the key factors to consider when evaluating oil casing materials is their mechanical properties. these properties, such as yield strength, tensile strength, and impact resistance, determine the ability of the casing to withstand the high pressures and stresses encountered during drilling and production. Higher strength materials are generally preferred for deeper wells or challenging drilling conditions, as they provide greater structural integrity and reliability.

oil field casing for saleAnother important consideration is the corrosion resistance of oil casing materials. Corrosion can significantly reduce the lifespan of casing and lead to costly repairs or replacements. By choosing materials with high corrosion resistance, operators can minimize the risk of casing failure and ensure the long-term integrity of the well. stainless steel and corrosion-resistant alloys are commonly used for their superior resistance to corrosive environments.

In addition to mechanical and corrosion properties, the thermal conductivity of oil casing materials is also a critical factor to consider. Thermal conductivity affects the ability of the casing to transfer heat away from the wellbore, which is essential for maintaining optimal drilling and production conditions. Materials with high thermal conductivity can help prevent overheating and ensure efficient heat dissipation, particularly in high-temperature drilling environments.

Furthermore, the weldability and machinability of oil casing materials are important considerations for fabrication and installation processes. Materials that are easily weldable and machinable can help reduce manufacturing costs and improve the efficiency of casing installation. Weldability is particularly crucial for ensuring the integrity of casing connections, while machinability affects the ease of cutting and sh APIng the casing to fit specific wellbore dimensions.

When comparing different oil casing materials, it is essential to consider their cost-effectiveness and availability. While high-performance materials may offer superior properties, they can also come at a higher cost and may be less readily available in certain regions. Operators must strike a balance between performance requirements and budget constraints to select the most suitable material for their specific drilling conditions.

In conclusion, the comparative indicators of oil casing materials are crucial for ensuring the success and longevity of oil drilling operations. By carefully evaluating the mechanical properties, corrosion resistance, thermal conductivity, weldability, machinability, cost-effectiveness, and availability of different materials, operators can make informed decisions that optimize the performance and reliability of their casing systems. Ultimately, choosing the right material composition for oil casing is essential for maximizing well productivity, minimizing downtime, and ensuring the safety and efficiency of oil drilling operations.

Significance of Size and weight specifications in Oil Casing Comparisons

When it comes to the oil and gas industry, the importance of selecting the right oil casing cannot be overstated. Oil casing plays a crucial role in the drilling and extraction process, providing structural support and protection for the wellbore. One of the key factors to consider when comparing different types of oil casing is their size and weight specifications.

Size and weight specifications are important indicators of the strength and durability of oil casing. The size of the casing refers to its diameter and wall thickness, while the weight specification indicates the amount of steel used in its construction. These specifications can vary significantly between different types of oil casing, and understanding their significance is essential for making informed decisions.

Size specifications are crucial for determining the compatibility of oil casing with other components of the wellbore, such as the drill pipe and production Tubing. Casing that is too large or too small may not fit properly, leading to potential issues during drilling and production. Additionally, the wall thickness of the casing is directly related to its strength and ability to withstand the pressures and stresses of the wellbore environment.

Weight specifications are also important indicators of the strength and durability of oil casing. Heavier casing typically indicates a thicker wall and more steel used in its construction, which can provide greater protection against corrosion, collapse, and other forms of damage. However, heavier casing may also be more difficult and costly to transport and install, so it is important to strike a balance between strength and practicality.

When comparing different types of oil casing, it is important to consider both size and weight specifications in conjunction with other factors, such as material composition, thread type, and connection design. Each of these factors can impact the performance and longevity of the casing in different ways, so a comprehensive evaluation is necessary to make an informed decision.

In addition to size and weight specifications, it is also important to consider the specific requirements of the wellbore and the surrounding environment. Factors such as depth, temperature, pressure, and corrosive elements can all influence the selection of oil casing. For example, wells drilled in high-pressure or high-temperature environments may require casing with thicker walls and higher weight specifications to ensure integrity and safety.

Overall, size and weight specifications are important comparative indicators of oil casing that should not be overlooked. By carefully evaluating these specifications in conjunction with other factors, such as material composition and environmental conditions, operators can select the right casing for their specific needs. Making informed decisions about oil casing can help improve drilling efficiency, reduce downtime, and enhance overall well performance.

Do oil pipes need bonding