Benefits of Using casing Hangers in Oil and gas Wells

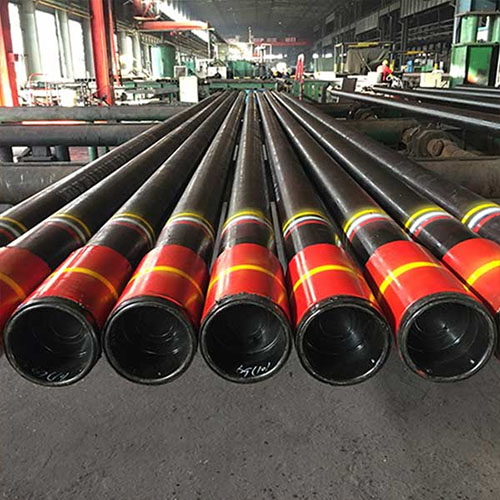

Casing hangers are an essential component in oil and gas wells, providing support and sealing capabilities for the casing strings that are run into the wellbore. There are several different models of casing hangers available on the market, each with its own unique features and benefits. In this article, we will focus on three popular models: the WFT-21, WFT-22, and WFT-29 casing hangers.

The WFT-21 casing hanger is a versatile and reliable option for oil and gas wells. It is designed to provide a secure connection between the casing string and the wellhead, ensuring that the casing is properly supported and sealed. The WFT-21 casing hanger is easy to install and can accommodate a wide range of casing sizes, making it a popular choice for many well operators.

FEP Coiled TubingAnother popular model is the WFT-22 casing hanger, which offers enhanced sealing capabilities and improved load-bearing capacity. The WFT-22 casing hanger is designed to withstand high pressures and temperatures, making it ideal for challenging well conditions. This casing hanger is also equipped with a metal-to-metal seal, ensuring a reliable and leak-free connection between the casing and the wellhead.

The WFT-29 casing hanger is a heavy-duty option for oil and gas wells that require extra support and sealing capabilities. This casing hanger is designed to handle extreme pressures and temperatures, making it suitable for deepwater and high-pressure wells. The WFT-29 casing hanger is also equipped with a lockdown feature, which provides additional security and stability during well operations.

Using casing hangers in oil and gas wells offers several benefits to well operators. One of the main advantages of using casing hangers is that they help to prevent casing collapse and maintain well integrity. Casing hangers provide support for the casing string, ensuring that it remains in place and does not buckle under the weight of the wellbore fluids.

oil Pipe news

Additionally, casing hangers help to create a seal between the casing and the wellhead, preventing fluid migration and maintaining well pressure. This is essential for well control and safety, as any leaks or breaches in the casing can lead to costly well control issues and environmental damage.

bmw 335d turbo oil feed pipeCasing hangers also play a crucial role in well completion and production operations. By providing a secure connection between the casing string and the wellhead, casing hangers allow for the installation of production tubing and other completion equipment. This ensures that the well can be brought into production efficiently and safely.

In conclusion, casing hangers are an essential component in oil and gas wells, providing support, sealing, and stability for the casing strings that are run into the wellbore. The WFT-21, WFT-22, and WFT-29 casing hangers are popular models that offer a range of features and benefits to well operators. By using casing hangers, operators can ensure the integrity and safety of their wells, as well as facilitate efficient well completion and production operations.

A Comparison of Casing Hanger Models WFT-21, WFT-22, and WFT-29

Casing hangers are an essential component in oil and gas well construction, providing support for the casing strings that line the wellbore. There are several different models of casing hangers available on the market, each with its own unique features and benefits. In this article, we will compare three popular casing hanger models: WFT-21, WFT-22, and WFT-29.

The WFT-21 casing hanger is a versatile and reliable option for a wide range of wellbore conditions. It is designed to support casing strings with diameters ranging from 4 1/2 inches to 20 inches, making it suitable for both onshore and offshore applications. The WFT-21 casing hanger features a slip-type design, which allows for easy installation and removal of the casing string. This model also includes a lockdown mechanism to prevent the casing from moving once it is in place.

In contrast, the WFT-22 casing hanger is specifically designed for deepwater drilling operations. This model is capable of supporting casing strings with diameters up to 36 inches, making it ideal for ultra-deepwater wells. The WFT-22 casing hanger features a hydraulic setting mechanism, which allows for precise control over the casing installation process. Additionally, this model includes a metal-to-metal seal to ensure a secure connection between the casing and the wellhead.

Finally, the WFT-29 casing hanger is a heavy-duty option for high-pressure and high-temperature wells. This model is designed to support casing strings with diameters up to 30 inches and can withstand pressures of up to 15,000 psi. The WFT-29 casing hanger features a threaded connection for easy installation and removal, as well as a metal-to-metal seal for added security. This model also includes a lockdown mechanism to prevent the casing from shifting during operation.

Overall, each of these casing hanger models offers unique advantages depending on the specific requirements of the wellbore. The WFT-21 is a versatile option suitable for a wide range of applications, while the WFT-22 is designed for deepwater drilling operations. The WFT-29, on the other hand, is a heavy-duty option for high-pressure and high-temperature wells.

When selecting a casing hanger model, it is important to consider factors such as wellbore conditions, casing size, and pressure requirements. Consulting with a qualified engineer or well construction specialist can help ensure that the correct casing hanger is chosen for the job. Additionally, regular maintenance and inspection of casing hangers are essential to ensure safe and efficient well operation.

In conclusion, casing hangers play a critical role in oil and gas well construction, providing support for casing strings and ensuring the integrity of the wellbore. The WFT-21, WFT-22, and WFT-29 casing hanger models each offer unique features and benefits, making them suitable for a variety of wellbore conditions. By carefully considering the specific requirements of the well, operators can select the appropriate casing hanger model to ensure safe and efficient well operation.