Benefits of Using a casing Hanger in Oil and gas Wells

A casing hanger is a critical component in oil and gas wells that plays a crucial role in supporting the casing string and ensuring the integrity of the wellbore. It is a device that is used to suspend and seal the casing in the wellbore, providing support and stability to the casing string as it is run into the well. Casing hangers are typically installed at the top of the wellhead and are designed to withstand the weight of the casing string and the pressure exerted by the wellbore fluids.

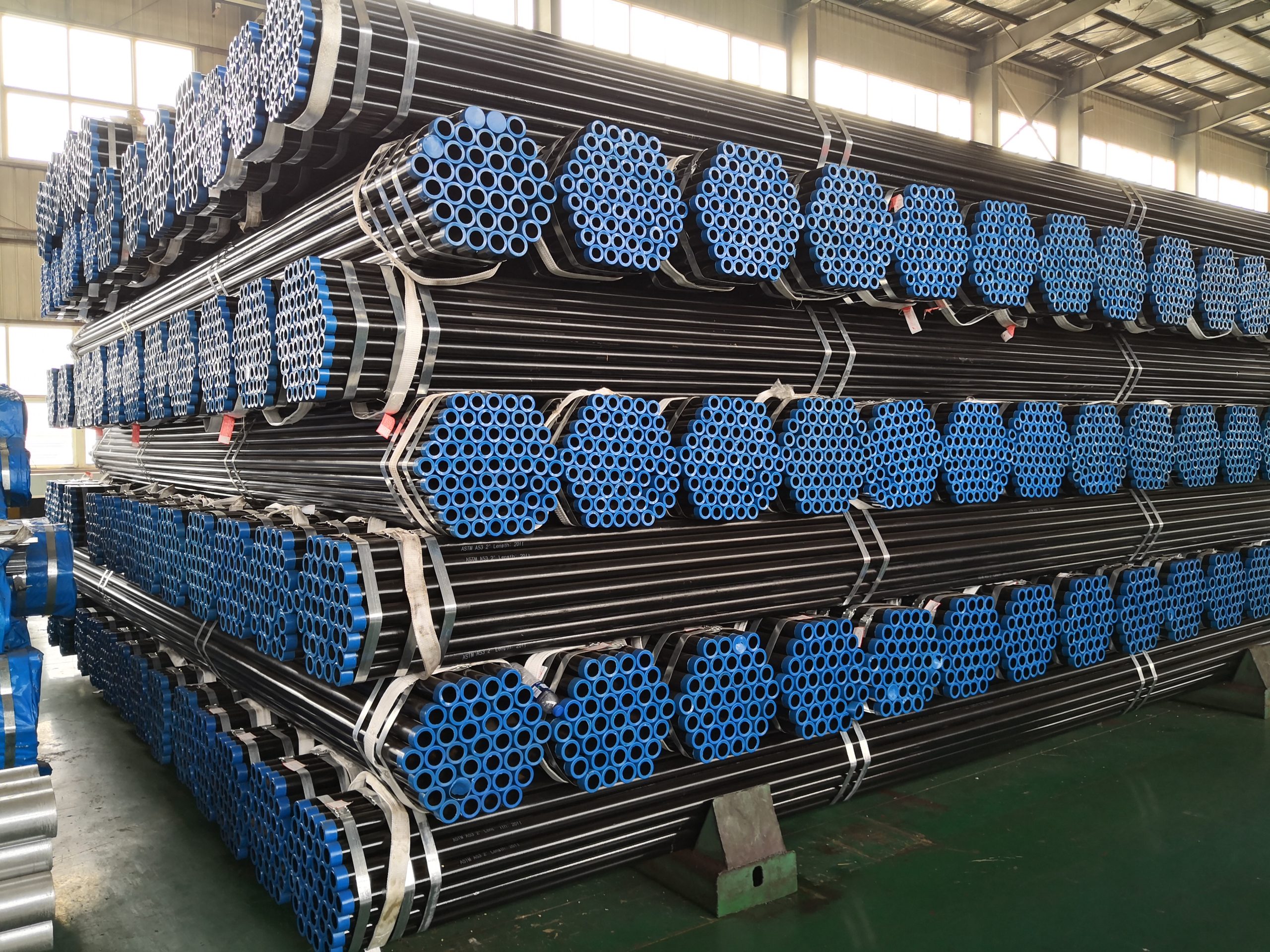

oil Pipe manufacturers usa

One of the key benefits of using a casing hanger in oil and gas wells is that it helps to prevent casing collapse and maintain the integrity of the wellbore. By supporting the weight of the casing string, the casing hanger helps to prevent the casing from buckling or collapsing under the pressure of the wellbore fluids. This is essential for ensuring the structural integrity of the well and preventing costly and potentially dangerous wellbore failures.

In addition to providing support for the casing string, casing hangers also help to seal the annular space between the casing and the wellbore, preventing the migration of fluids and gases from one zone to another. This is important for maintaining well control and preventing the contamination of groundwater sources. By creating a seal between the casing and the wellbore, casing hangers help to isolate different zones within the well and prevent the mixing of fluids and gases that could lead to wellbore instability or environmental damage.

casing pipe China good factory

Another benefit of using a casing hanger in oil and gas wells is that it helps to facilitate the installation and removal of the casing string. Casing hangers are designed to be easily installed and removed, allowing for quick and efficient casing operations. This is important for reducing downtime and increasing the efficiency of well construction and completion operations. By providing a secure and stable platform for the casing string, casing hangers help to streamline the casing installation process and ensure that the casing is properly supported and aligned within the wellbore.

oil and gas pipe insulation job descriptionFurthermore, casing hangers are designed to withstand the harsh operating conditions encountered in oil and gas wells, including high temperatures, pressures, and corrosive fluids. they are typically made from high-strength materials such as carbon steel or stainless steel, which are able to withstand the extreme conditions found in wellbore environments. This ensures that the casing hanger will not fail under the stresses imposed by the wellbore fluids and will provide reliable support for the casing string throughout the life of the well.

In conclusion, the benefits of using a casing hanger in oil and gas wells are numerous and significant. From providing support and stability to the casing string, to sealing the annular space and facilitating casing operations, casing hangers play a critical role in ensuring the integrity and efficiency of well construction and completion operations. By choosing a high-quality casing hanger and installing it correctly, operators can help to ensure the success and longevity of their oil and gas wells.