Advantages of Using API casing Table in Oil and gas industry

API casing tables are an essential tool in the oil and gas industry, providing valuable information on the dimensions and properties of casing Pipes used in drilling operations. these tables are created and maintained by the american petroleum Institute (API), a leading organization in the industry that sets standards for equipment and materials used in oil and gas exploration and production.

One of the key advantages of using API casing tables is the standardized information they provide. By following the API standards, companies can ensure that the casing pipes they use meet the necessary requirements for strength, size, and performance. This helps to improve safety and efficiency in drilling operations, as well as ensuring compliance with industry regulations.

Another advantage of API casing tables is the wealth of information they contain. These tables provide detailed specifications for a wide range of casing sizes and grades, allowing companies to select the most appropriate casing for their specific drilling conditions. This information includes dimensions, weights, and mechanical properties of the casing pipes, as well as recommended practices for handling, storage, and installation.

In addition to providing technical information, API casing tables also serve as a valuable reference tool for engineers, technicians, and other professionals in the oil and gas industry. By consulting these tables, industry professionals can quickly access the information they need to make informed decisions about casing selection, design, and installation. This can help to streamline the decision-making process and improve overall project efficiency.

Furthermore, API casing tables are regularly updated to reflect changes in technology, industry best practices, and regulatory requirements. This ensures that the information provided in these tables is current and accurate, helping companies to stay ahead of the curve in a rapidly evolving industry. By using the latest API standards, companies can benefit from the most up-to-date information on casing materials, design, and performance.

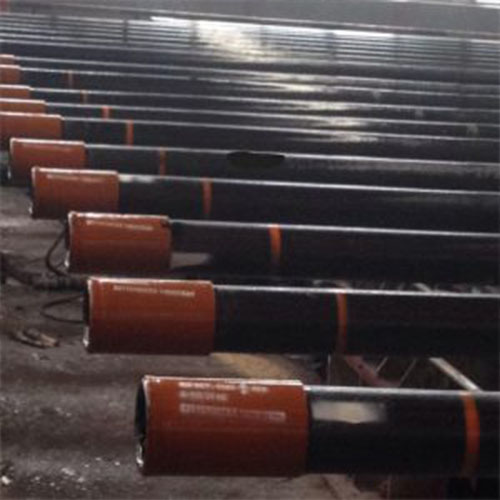

Oil CasingOverall, the advantages of using API casing tables in the oil and gas industry are clear. These tables provide standardized, detailed information on casing pipes, helping companies to select the most appropriate materials for their drilling operations. They also serve as a valuable reference tool for industry professionals, providing quick access to essential information on casing specifications and best practices. By staying up-to-date with the latest API standards, companies can ensure that they are using the most current and reliable information available, helping to improve safety, efficiency, and compliance in their drilling operations.

How to Select the Right API Casing Size for Your Well

API casing is an essential component in the construction of oil and gas wells. It serves as a protective barrier that prevents the wellbore from collapsing and ensures the integrity of the well. When selecting the right API casing size for your well, it is crucial to consider various factors such as well depth, formation characteristics, and production requirements.

oil pipes 6.0 powerstrokeThe API casing table provides a comprehensive guide to help engineers and operators determine the appropriate casing size for a particular well. The table includes information on casing dimensions, weight, and thread type, making it easier to select the right casing for the job. By understanding how to interpret the API casing table, you can ensure that your well is constructed to the highest standards and meets all regulatory requirements.

One of the key factors to consider when selecting the right API casing size is the well depth. The depth of the well will determine the length and weight of the casing required to support the wellbore. In general, deeper wells will require larger and heavier casing to withstand the pressure and weight of the surrounding formations. By consulting the API casing table, you can easily determine the appropriate casing size based on the depth of your well.

oil pipe pressure drop calculationAnother important consideration when selecting API casing is the formation characteristics of the well. different formations have varying levels of pressure, temperature, and corrosiveness, which can impact the performance of the casing. It is essential to choose casing that can withstand the specific conditions of the well to ensure its longevity and integrity. The API casing table provides information on the material grade and strength of each casing size, allowing you to select the most suitable option for your well.

Production requirements also play a significant role in determining the right API casing size for a well. The production rate, fluid type, and well completion design will influence the selection of casing to ensure optimal performance and efficiency. By considering these factors in conjunction with the information provided in the API casing table, you can make an informed decision that meets the needs of your well.

In addition to well depth, formation characteristics, and production requirements, it is essential to consider the thread type when selecting API casing. The thread type determines how the casing will be connected and secured in the wellbore, ensuring a tight seal and preventing leaks. The API casing table includes information on the thread type for each casing size, allowing you to choose the appropriate option for your well.

Overall, the API casing table is a valuable resource for engineers and operators involved in the construction of oil and gas wells. By understanding how to interpret the information provided in the table, you can select the right casing size for your well based on factors such as well depth, formation characteristics, production requirements, and thread type. By choosing the appropriate casing, you can ensure the integrity and longevity of your well, ultimately leading to a successful and productive operation.