Analyzing API casing Strengths: A Comprehensive guide for drillers

Analyzing API Casing Strengths: A Comprehensive Guide for Drillers

When it comes to drilling operations, the strength and integrity of the casing are paramount. API casing, standardized by the american petroleum Institute, undergoes rigorous testing to ensure it meets specific requirements for strength, durability, and performance in demanding Oil and gas environments. Drillers rely on API casing to provide a robust barrier that supports the wellbore and protects against potential hazards such as pressure, corrosion, and mechanical stress.

Understanding the strengths of API casing requires a thorough audit of its properties and performance characteristics. This comprehensive guide aims to provide drillers with valuable insights into the factors that influence API casing strength and the importance of conducting audits to ensure compliance and safety.

API casing strength is determined by various factors, including material composition, manufacturing processes, and dimensional specifications. steel is the most common material used for API casing due to its high strength, corrosion resistance, and suitability for downhole environments. manufacturers employ advanced metallurgical techniques to enhance the mechanical properties of the steel, such as yield strength, tensile strength, and hardness, to meet API standards.

The manufacturing process also plays a crucial role in determining the quality and integrity of API casing. stringent quality control measures are implemented throughout fabrication, including raw material inspection, heat treatment, machining, and non-destructive testing. these processes help identify any defects or inconsistencies that could compromise the strength and reliability of the casing.

Furthermore, dimensional specifications, such as outer diameter, wall thickness, and thread design, are critical factors in ensuring proper fit and performance of API casing in the wellbore. Deviations from specified dimensions can affect the structural integrity of the casing and may lead to operational challenges or integrity issues during drilling and production operations.

To assess API casing strengths effectively, drillers must conduct thorough audits of both the material properties and dimensional characteristics. This involves performing visual inspections, dimensional measurements, and mechanical testing to evaluate compliance with API standards and project requirements. Additionally, drillers should collaborate closely with casing manufacturers and suppliers to address any concerns or discrepancies identified during the audit process.

Transitional phrases like “furthermore” help connect ideas, making it easier for the reader to follow along and understand the content. For instance, after discussing the manufacturing process, transitioning to the importance of dimensional specifications maintains the logical flow of the article.

Ensuring Safety and Compliance: Conducting Audits of API Casing Strengths in Drilling Operations

Ensuring Safety and Compliance: Conducting Audits of API Casing Strengths in Drilling Operations

Drilling operations in the oil and gas industry are complex and inherently risky endeavors. The integrity of equipment used in these operations, particularly casing, is paramount to ensuring safety and preventing environmental disasters. The American Petroleum Institute (API) sets standards for casing strength to guarantee the reliability and durability of equipment under the demanding conditions of drilling. Conducting audits of API casing strengths is an essential practice for drillers to maintain compliance and uphold safety standards.

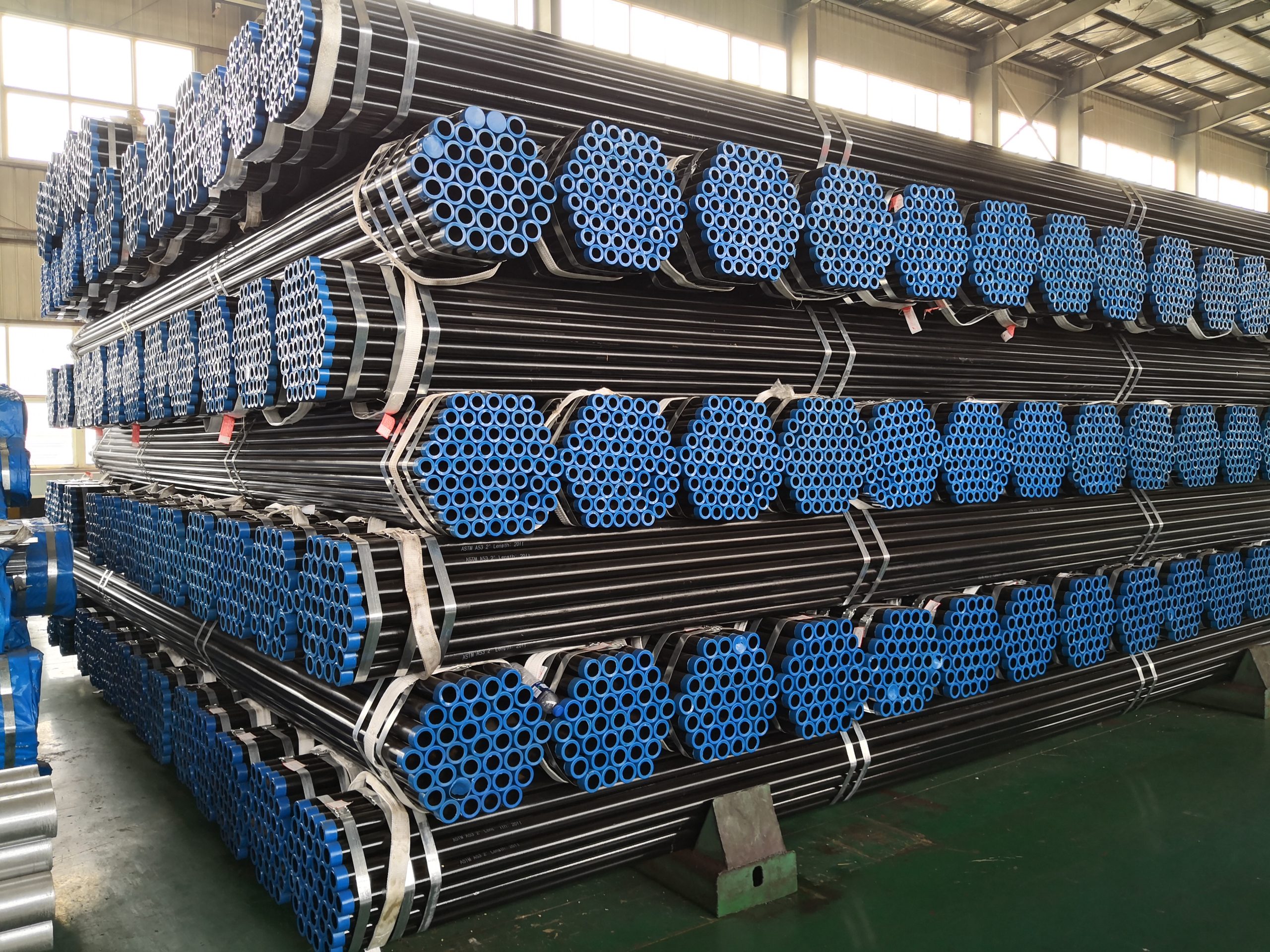

surface casing oil and gasAPI casing strength standards are designed to withstand the pressures and stresses encountered during drilling and production processes. These standards cover various aspects, including material specifications, dimensional tolerances, and performance requirements. Adhering to these standards is crucial for preventing casing failures that could result in well blowouts, oil spills, and other catastrophic incidents. Auditing the compliance of casing materials and specifications with API standards ensures that equipment meets the necessary strength criteria for safe drilling operations.

One of the primary reasons for conducting audits of API casing strengths is to assess the integrity of equipment before and during drilling activities. By thoroughly examining casing materials, dimensions, and performance characteristics, auditors can identify any deviations from API standards that may compromise safety and reliability. This proactive approach allows drillers to address potential issues before they escalate into major problems, mitigating risks and ensuring operational continuity.

During audits, drillers evaluate various factors that influence casing strength, such as material quality, manufacturing processes, and installation techniques. They verify that casing materials meet API specifications for strength, corrosion resistance, and durability. Additionally, auditors assess dimensional tolerances to ensure proper fit and compatibility with other components in the drilling system. By scrutinizing every aspect of casing construction and installation, drillers can identify weaknesses and vulnerabilities that could compromise structural integrity.

Audits of API casing strengths also play a crucial role in regulatory compliance. Government agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States, enforce regulations to safeguard workers and the environment in drilling operations. Compliance with API standards is often a prerequisite for obtaining permits and licenses for drilling activities. By conducting thorough audits of casing strengths, drillers demonstrate their commitment to meeting regulatory requirements and operating responsibly within legal frameworks.

In addition to regulatory compliance, audits of API casing strengths contribute to continuous improvement in drilling practices. By identifying areas for enhancement in casing design, material selection, and installation procedures, drillers can optimize equipment performance and reliability. This ongoing process of evaluation and refinement helps drive innovation in drilling technologies and fosters a culture of safety and excellence within the industry.

Transitioning from auditing to implementing corrective actions is essential for ensuring the effectiveness of API casing strength audits. Upon identifying deviations from API standards or areas for improvement, drillers must take prompt and decisive measures to rectify issues and prevent recurrence. This may involve replacing substandard casing materials, improving quality control processes, or enhancing training programs for personnel involved in drilling operations. By addressing root causes and implementing preventive measures, drillers can strengthen their overall safety and compliance posture.

In conclusion, audits of API casing strengths are vital for ensuring the safety, compliance, and efficiency of drilling operations in the oil and gas industry. By rigorously evaluating casing materials, dimensions, and performance against API standards, drillers can identify and mitigate risks before they escalate into serious incidents. These audits not only safeguard workers and the environment but also contribute to continuous improvement and innovation in drilling practices. By embracing the principles of safety, compliance, and excellence, drillers can uphold industry standards and maintain public trust in their operations.